The main lesson is probably already clear: suction and vacuum excavators are now the reigning supreme over traditional digging methods. They enable more precision, rapidity, power, and safety, among other benefits. But how do you distinguish between good and unreliable products? The real-world consequences of not using the proper equipment can be costly, negatively impact your business financially and reputationally, and make you regret your decision, even in the best-case scenarios. It’s therefore essential to base your decision on a set of considerations, because there’s no such thing as two similar sites, and each encountered challenge will be like none you’ve met before.

What to choose between a suction and a vacuum excavator? What knowledge will guide your decision-making?

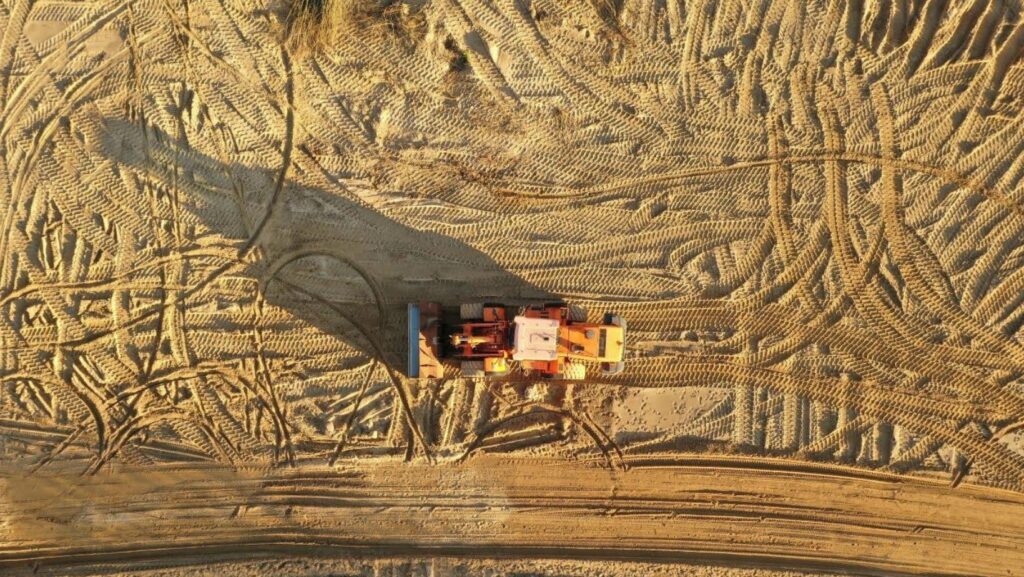

Photo source: https://unsplash.com/photos/an-aerial-view-of-a-tractor-trailer-in-a-field-hWtLz3FWA8w

Differentiating the Two

A longer explanation of both vacuum and suction excavators is that they’re non-destructive machines for digging. They don’t rely on brute force like traditional equipment does, but on water or air pressure that loosens soil and debris in order to suck the materials into a storage tank.

Vacuum excavators typically use high-pressure water, also known as hydro excavation, or compressed air to moisten the soil and remove the debris with a vacuum hose. They’re specifically helpful if your construction is taking place in an urban area, where the underground space conceals all sorts of pipes and precision is vital. Importantly, they commonly come in smaller, trailer- or truck-mounted units. On the other hand, suction excavators are larger and offer more suction power, making them reliable for heavier-duty undertakings. You’ll need a suction excavator if your project involves removing larger soil volumes and lifting bulkier objects, such as stones, bricks, tree roots, or relics.

With this in mind, let’s explore the boxes your operator should tick to be the right match for your project.

Operator Excellence

When it comes to suction and vacuum excavators, the operator’s quality and competence can make or break your project. Credentials like the CPCS A78 (A-H), which ensure that the operator adheres to Health, Safety & Environment rules and recommendations, are a green flag, but only possessing this type of certificate isn’t enough to guarantee excellence – it signals a basic competency level. Having additional credits as an operator, such as those resulting from the superior training undertaken under CPCS A78 courses, which cover safety procedures, utility awareness, maintenance, and hands-on excavator operations, is a further indication of excellence.

These advanced qualifications indicate more than the obligatory compliance – they’re signs your targeted operator has a higher skill level and the readiness and adaptability to deal with sudden challenges. This type of assurance isn’t an extravagance, but a way to secure your project’s success and efficiency.

Sector Specialty

Is your targeted operator able to operate within your sector? The type of excavation project, its complexity, and even the chosen location can influence the type of machinery required. For instance, you’ll need a completely different model of machine when needing to remove debris from an unstable or uneven terrain than you’d need for a compact urban dig with easy access. Not every company can provide you with the same level of fleet versatility, and this is where specialist providers start to stand apart from average hire services.

Some projects necessitate equipment that works in tight spaces, while others call for gear that’s strong enough to handle very bulky material or treacherous ground. In such situations, it’s best to work with an operator that offers expert solutions, like vacuum excavator hire, to have peace of mind that the team won’t only use the most suitable machinery but also handle any unforeseen challenges that may arise along the way. The right choice of gear doesn’t just make your project possible; it makes it faster, safer, and cheaper, to say the least.

Equipment Condition and Maintenance

You can come across the busiest operator – the benchmark in the field, which gets booked months or even years in advance. But does this high rate of demand guarantee that their machinery will be in perfect condition and ready to meet all your project needs? Not necessarily, because some companies may prioritize other aspects over regular maintenance and audit checks. This is a critical concern, as the equipment’s condition and reliability can ultimately make or break your project, and you can’t afford to make a poor collaboration decision.

Before committing to a hire or purchase, assess the condition of the excavator itself, be it for suctioning or vacuuming. Request certifications or documents that demonstrate the operator adheres to the manufacturer-recommended servicing schedule – the right, professional operator will willingly provide them, often without even needing to be asked. Well-kept excavators work more efficiently and can reduce risks of on-site breakdowns, thus eliminating the threat of finishing your project later than discussed or incurring additional costs. Modern gear typically features built-in safety mechanisms, automated controls, and filtration systems – these help mitigate operational risks, but only when the apparatus is in excellent condition.

Capacity for Adapting to Challenges

Rarely can one have a project unfolding exactly as planned – what lies beneath our feet often holds surprises. Soil conditions may vary unexpectedly due to various factors, including weather conditions. The underground utility structure may be more complicated than initially thought, and access blockages may arise unexpectedly.

The best companies, however, are aware of this reality and can anticipate challenges, devising flexible solutions. For instance, they’d have a breadth of excavators ready to use, adaptable to all sorts of site scales, as well as workers trained to be flexible and adapt their approach depending on how working conditions change.

Flawless record

You need to ensure that your target company isn’t troubled by penalties or disciplinary inconveniences that might indicate a potential negative experience. A reliable operator has a positive performance, an excellent track record, and a commitment to maintaining a high standard – achievements that can be verified and learned about through a quick online search and background check.

At the same time, it needs to have a strike-free record. All underground utility strikes incurred during excavations result in a set of indirect and direct costs that can significantly impact the contractor and your project. A utility strike can cost thousands, if not millions of dollars, depending on your project’s scale.

Conclusion

Selecting the right vacuum or suction excavator, as well as the right operator, is about more than just comparing prices or specifications – it’s about your targeted company checking all the boxes presented above. The right choice will empower you to tackle even the most complex excavation challenges confidently, so pick wisely!